The Manual to Manhood: A Comprehensive Guide

This comprehensive guide explores healthy masculinity, encompassing financial responsibility, emotional intelligence, and navigating relationships – a journey towards meaning and purpose.

Defining Manhood in the 21st Century

Contemporary manhood transcends traditional stereotypes, evolving beyond rigid expectations. It’s no longer solely defined by financial success or stoicism, but by a holistic integration of emotional intelligence, social responsibility, and personal fulfillment. This necessitates a re-evaluation of learned behaviors and a conscious effort to dismantle toxic masculinity’s harmful influences.

The absence of clear, positive role models often leaves men navigating this terrain without guidance, relying instead on peer influence. A healthy approach involves understanding and expressing emotions, fostering genuine connections, and prioritizing both physical and mental wellbeing. Ultimately, defining manhood today centers on authenticity, integrity, and a commitment to continuous self-improvement.

The Elementalist View of Manhood

The Elementalist perspective suggests manhood isn’t a prescribed set of traits, but rather, inherent characteristics simply taken for granted as belonging to men. This viewpoint, shared by individuals like Glenn and Denton, implies a foundational understanding of what constitutes masculinity, existing independently of cultural dictates or societal pressures.

However, this doesn’t negate the influence of learning and performance. Men actively perform manhood, adapting behaviors based on context and observation. The challenge lies in discerning authentic self-expression from externally imposed expectations. Recognizing these inherent qualities, while acknowledging the learned aspects, is crucial for a nuanced understanding of masculinity.

The Role of Role Models in Masculinity Development

In the absence of formalized rituals and guidance from mature male figures, boys often navigate towards manhood by observing their peers. This highlights the critical role of role models in shaping masculine identity. Without positive adult mentorship, young men may adopt behaviors based on limited or even detrimental examples.

The literature emphasizes how males learn to perform manhood through observation and imitation. Mature masculinity, modeled by responsible adults, provides a crucial framework for healthy development. This underscores the importance of intentional mentorship and the need for positive male influences in a boy’s life, guiding them towards constructive expressions of manhood.

Performing Manhood: Learned Behaviors and Variations

Manhood isn’t inherent; it’s largely performed – a collection of learned behaviors shaped by cultural context and individual experiences. The ways in which men enact masculinity are diverse, varying significantly based on upbringing, social circles, and personal choices. This performance isn’t simply imitation, but an active construction of identity.

Understanding these variations is crucial. The literature reveals how “manhood acts” differ, influenced by a multitude of factors. Examining these recurring themes allows for a nuanced appreciation of masculinity, acknowledging that there isn’t one single “correct” way to be a man, but rather a spectrum of expressions.

Historical Context of Masculinity

Masculinity’s definition has dramatically evolved, from antebellum ideals fueling the Civil War to Victorian-era literature and evolving encyclopedia entries.

Antebellum Masculinity and the Civil War

The dissertation meticulously explores the nature of masculinity prevalent in the antebellum South and its significant role in instigating the American Civil War. It concentrates its analytical focus on two crucial aspects of this period: honor and duty. These weren’t merely personal virtues, but deeply ingrained societal expectations defining what it meant to be a man.

This rigid code demanded displays of courage, self-reliance, and a willingness to defend one’s reputation – often through violence. The escalating tensions surrounding slavery directly intersected with these masculine ideals, creating a volatile environment where defending Southern honor became inextricably linked to preserving the institution.

Consequently, the call to arms wasn’t simply a political decision, but a fulfillment of masculine obligation, driving men towards conflict.

Masculinity in Victorian Era Literature (Boys Own Paper)

By meticulously examining recurring themes of masculinity within the Boys Own Paper, this study reveals the publication’s internal struggles. It attempted to balance the promotion of traditional masculine virtues – courage, duty, and physical prowess – with evolving societal expectations. The paper frequently presented narratives of adventure, exploration, and imperial service, explicitly designed to mold young boys into ideal Victorian gentlemen.

However, it also grappled with anxieties surrounding the changing nature of masculinity, particularly the tension between public heroism and private emotional life. The Boys Own Paper, therefore, offers a fascinating window into the construction of manhood during a period of significant social and cultural transformation.

The Evolution of Masculinity Through Historical Encyclopedia

American Masculinities: A Historical Encyclopedia represents a pioneering reference work, meticulously detailing the developments within the expanding field of men’s studies. This resource charts the complex and multifaceted evolution of masculinity across American history, moving beyond simplistic or monolithic definitions. It acknowledges the diverse experiences of men shaped by race, class, sexuality, and regional differences.

The encyclopedia provides invaluable insights into how conceptions of manhood have been constructed, contested, and transformed over time, offering a nuanced understanding of this continually evolving social construct.

Deconstructing Hypermasculinity

Programs aim to dismantle harmful hypermasculinity within correctional facilities, assisting inmates in redefining masculinity towards healthier expressions and behaviors.

Addressing Toxic Masculinity in Modern Society

Modern society grapples with the detrimental effects of toxic masculinity, often stemming from a lack of positive male role models and culturally-prescribed rituals for maturation. This absence leads boys to seek guidance from peers, potentially internalizing harmful behaviors.

The challenge lies in recognizing and dismantling ingrained societal expectations that equate masculinity with dominance, emotional suppression, and aggression. A crucial step involves fostering open conversations about vulnerability, empathy, and healthy emotional expression.

Deconstructing these norms requires a conscious effort to redefine masculinity, promoting values like respect, responsibility, and genuine connection – moving beyond superficial displays of power and towards authentic selfhood.

Redefining Masculinity within Correctional Facilities

Correctional facilities present a unique environment where hypermasculinity often thrives, contributing to violence and hindering rehabilitation. Programs are increasingly focused on deconstructing these harmful norms and offering inmates alternative frameworks for understanding masculinity.

These initiatives aim to challenge ingrained beliefs about power, control, and emotional expression, encouraging participants to explore vulnerability and develop healthier coping mechanisms. The goal isn’t to eliminate masculinity, but to redefine it – shifting the focus from dominance to responsibility and respect.

By fostering self-awareness and promoting empathy, these programs empower inmates to break cycles of harmful behavior and build a more positive self-image, crucial for successful reintegration into society;

Core Components of Healthy Masculinity

Healthy masculinity centers on financial stability, pursuing personal interests, and hobbies, fostering a well-rounded life beyond work and societal expectations.

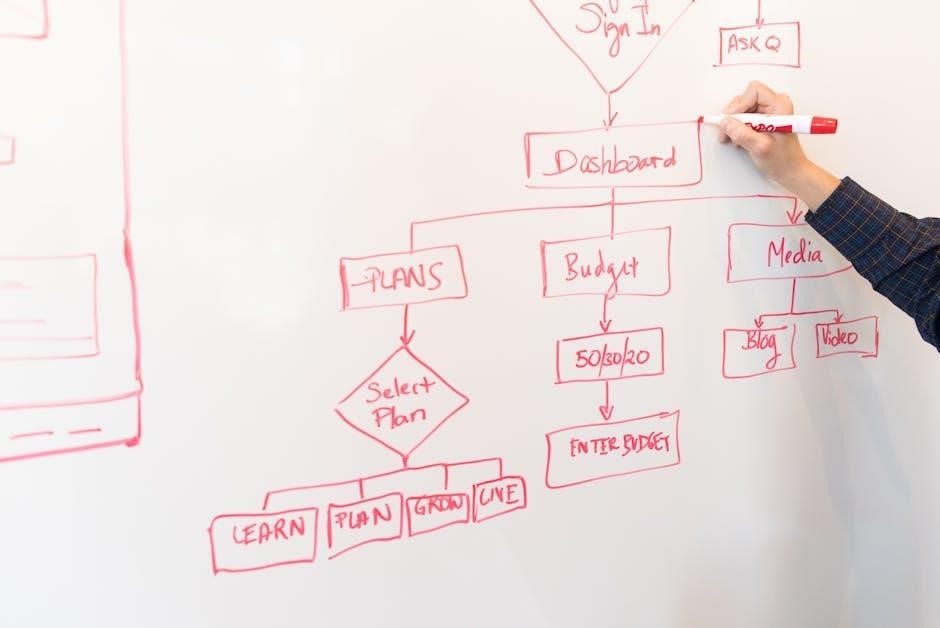

Financial Responsibility and Career Focus

A cornerstone of healthy masculinity involves embracing financial responsibility, extending beyond merely acquiring wealth. It’s about understanding the value of work, not solely for monetary gain, but for its contribution to social relations and personal fulfillment. However, the pursuit shouldn’t devolve into a relentless, unmeaning desire for money, eclipsing intrinsic rewards.

Career focus, therefore, isn’t about climbing the corporate ladder at all costs, but about finding work that aligns with one’s values and provides a sense of purpose. This approach fosters a conscious connection between effort, reward, and societal contribution, building a foundation for a meaningful and balanced life.

The Importance of Interests and Hobbies

Cultivating interests and hobbies is vital for a well-rounded masculine identity, moving beyond solely career or financial pursuits. These passions provide avenues for self-expression, stress relief, and personal growth, fostering a sense of individual identity separate from societal expectations.

A man’s hobbies aren’t frivolous distractions, but essential components of a fulfilling life. They offer opportunities for learning, creativity, and connection with others who share similar passions. Finding absorbing interests, like college football, can enrich life, offering a counterbalance to work and responsibility, and promoting overall wellbeing.

Navigating Relationships

Building strong connections – both romantic and platonic – requires emotional intelligence, open communication, and a commitment to mutual respect and understanding.

Building Healthy Romantic Relationships

Establishing a foundation of trust, respect, and open communication is paramount in fostering a healthy romantic partnership. This involves actively listening to your partner, validating their feelings, and expressing your own needs and vulnerabilities honestly. Shared interests and hobbies can strengthen the bond, but individual pursuits are equally vital for maintaining personal identity.

Healthy relationships aren’t about control or possessiveness, but about mutual support and growth. Navigating conflict constructively, with empathy and a willingness to compromise, is crucial. Remember that a fulfilling relationship requires consistent effort, understanding, and a shared commitment to building a future together, prioritizing emotional connection alongside practical considerations.

Fostering Strong Male Friendships

Genuine male friendships offer invaluable support, camaraderie, and a sense of belonging, crucial for overall wellbeing. These bonds are built on shared experiences, mutual respect, and the ability to be vulnerable with one another – moving beyond superficial interactions. Actively investing time and effort into nurturing these relationships is essential, demonstrating loyalty and offering support during both triumphs and challenges.

Strong friendships provide a safe space for honest communication, constructive feedback, and emotional processing. It’s about being present, listening without judgment, and celebrating each other’s successes. These connections contribute significantly to a man’s sense of identity and resilience, offering a vital counterbalance to societal pressures and expectations.

Emotional Intelligence and Self-Awareness

Developing emotional intelligence involves understanding, expressing, and managing emotions effectively – fostering resilience and building stronger connections with oneself and others.

Understanding and Expressing Emotions

Traditionally, societal norms have often discouraged men from openly acknowledging or expressing their emotions, leading to internalized struggles and potential harm. However, a cornerstone of healthy masculinity lies in cultivating emotional literacy – the ability to identify, understand, and articulate one’s feelings.

This isn’t about abandoning strength or stoicism; rather, it’s about recognizing that emotions are a natural and vital part of the human experience. Learning to name emotions – whether it’s sadness, anger, joy, or vulnerability – allows for healthier processing and prevents them from manifesting in destructive ways.

Expressing emotions constructively, through open communication and healthy outlets, fosters deeper connections with others and promotes overall wellbeing. It requires courage and self-awareness, but the rewards are immeasurable.

Developing Emotional Resilience

Life inevitably presents challenges, setbacks, and moments of profound emotional distress. Developing emotional resilience – the capacity to bounce back from adversity – is therefore crucial for navigating the complexities of manhood. This isn’t about avoiding pain, but about learning to cope with it effectively.

Resilience is built through self-awareness, strong social connections, and the cultivation of healthy coping mechanisms. Recognizing personal strengths, practicing self-compassion, and seeking support when needed are all vital components.

Furthermore, reframing negative experiences as opportunities for growth, and focusing on what can be controlled, fosters a sense of agency and empowers individuals to overcome obstacles. Emotional resilience isn’t a fixed trait, but a skill that can be honed over time.

Physical and Mental Wellbeing

Prioritizing both physical and mental health is fundamental to a fulfilling life, demanding consistent effort and, when necessary, proactively seeking support.

Prioritizing Physical Health

A cornerstone of robust manhood lies in actively prioritizing physical wellbeing; This isn’t merely about achieving a certain physique, but cultivating a lifestyle that supports sustained energy, resilience, and longevity. Regular exercise, tailored to individual capabilities and preferences, is paramount – whether it’s engaging in team sports like college football, or pursuing individual activities.

Nutritional awareness is equally crucial; fueling the body with wholesome foods provides the necessary building blocks for optimal function. Consistent sleep patterns are often overlooked, yet profoundly impact both physical and mental performance. Proactive health screenings and preventative care are not signs of weakness, but demonstrations of self-respect and responsibility, ensuring a long and vibrant life.

Maintaining Mental Health and Seeking Support

True strength in manhood encompasses acknowledging and nurturing mental wellbeing. It requires dismantling the outdated notion that vulnerability equates to weakness, and embracing emotional self-awareness. Developing emotional resilience – the ability to navigate setbacks and failures – is vital for sustained personal growth.

Actively seeking support when needed isn’t a sign of failing, but a demonstration of courage and self-respect. This could involve confiding in trusted friends, family members, or qualified professionals. Prioritizing mindfulness, practicing stress-reduction techniques, and cultivating a positive self-image are essential components of a healthy mental landscape.

Social Responsibility and Ethics

A cornerstone of mature manhood involves contributing positively to the community and consistently making ethical decisions, reflecting integrity and compassion.

Contributing to Community

Genuine manhood extends beyond personal success, demanding active participation and contribution to the broader community. This isn’t merely about charitable donations, though those are valuable; it’s about investing time, skills, and energy into initiatives that uplift others. Consider volunteering at local organizations, mentoring youth, or participating in civic duties.

A man’s impact is amplified when he uses his abilities to address societal needs, fostering a sense of collective well-being. This demonstrates a commitment to something larger than oneself, embodying responsibility and a desire to leave a positive legacy. It’s about building a stronger, more equitable society for future generations, showcasing true character.

Ethical Decision-Making

A cornerstone of healthy masculinity is unwavering ethical conduct. This means consistently choosing integrity over expediency, even when faced with difficult choices. It requires a strong moral compass, guided by principles of honesty, fairness, and respect for others. Ethical decision-making isn’t simply avoiding illegal acts; it’s about navigating gray areas with thoughtfulness and compassion.

True manhood demands accountability for one’s actions and a willingness to admit mistakes. It’s about prioritizing long-term values over short-term gains, building trust through consistent ethical behavior, and setting a positive example for those around you. This builds character and fosters respect.

The Pursuit of Meaning and Purpose

Finding value in work, social connections, and intrinsic rewards—avoiding materialism—is crucial for a fulfilling life, defining a man’s purpose and direction.

Finding Value in Work and Social Connections

A man’s work should transcend mere financial gain, evolving into a source of genuine satisfaction and a contribution to something larger than himself. However, work shouldn’t become solely a pursuit of money, losing its inherent value and connection to social responsibility.

Equally vital are strong social connections, fostering a sense of belonging and mutual support. These relationships provide emotional resilience and a shared understanding of life’s challenges.

True fulfillment arises not from accumulating possessions, but from cultivating meaningful experiences and nurturing authentic bonds with others, enriching life’s journey.

Avoiding Materialism and Focusing on Intrinsic Rewards

The pursuit of happiness often gets misdirected towards material possessions, creating a cycle of dissatisfaction. A truly fulfilling life, however, centers on intrinsic rewards – those derived from personal growth, meaningful work, and strong relationships.

Shifting focus from “having” to “being” allows a man to find value in experiences, contributions, and the development of his character. This involves recognizing that genuine worth isn’t measured by wealth or status, but by integrity and purpose.

Embracing this perspective fosters contentment and resilience, shielding against the fleeting allure of materialism.

Overcoming Challenges to Manhood

Navigating societal pressures and setbacks requires resilience, self-awareness, and a commitment to personal growth – essential components of a fulfilling manhood journey.

Addressing Societal Pressures

Modern society often imposes rigid expectations on men, fostering anxieties around performance, success, and emotional expression. These pressures can manifest as hypermasculinity, hindering authentic self-discovery and healthy relationships.

The key lies in recognizing these external forces and actively challenging limiting beliefs. Developing emotional intelligence allows for navigating these expectations without sacrificing personal values or wellbeing.

Furthermore, understanding that vulnerability isn’t weakness, but strength, is crucial. Rejecting the notion of a singular “correct” way to be a man empowers individuals to define their own masculinity, fostering resilience against societal constraints and promoting genuine self-acceptance.

Dealing with Failure and Setbacks

Failure is an inevitable component of life, yet societal pressures often discourage men from acknowledging vulnerability or seeking support when facing setbacks. A healthy approach involves reframing failure not as a reflection of personal worth, but as a valuable learning opportunity.

Developing emotional resilience is paramount. This includes acknowledging disappointment, processing emotions constructively, and avoiding self-blame.

Crucially, seeking mentorship or building a strong support network provides a safe space to discuss challenges and gain perspective. Embracing a growth mindset – believing abilities can be developed through dedication and hard work – fosters perseverance and ultimately, a stronger sense of self.

The Future of Manhood

Manhood’s future demands adapting to evolving gender roles and embracing inclusivity, redefining masculinity beyond traditional norms for a more equitable and fulfilling existence.

Adapting to Changing Gender Roles

The evolving landscape of gender necessitates a re-evaluation of traditional masculine expectations. Contemporary manhood isn’t about rigid adherence to outdated norms, but rather embracing fluidity and challenging preconceived notions. This adaptation requires acknowledging the societal shifts and recognizing the validity of diverse expressions of identity.

Crucially, it involves dismantling harmful stereotypes that limit both men and women. A healthy approach to masculinity in the 21st century prioritizes emotional openness, collaborative partnerships, and respect for all genders. It’s about fostering a society where individuals are free to define themselves, unburdened by restrictive gender roles, and where strength is found in vulnerability and empathy.

Embracing a More Inclusive Definition of Masculinity

A truly comprehensive understanding of manhood necessitates moving beyond narrow, prescriptive definitions. Inclusivity means recognizing that masculinity manifests diversely, shaped by individual experiences, cultural backgrounds, and personal values. It’s about acknowledging that strength isn’t solely defined by physical prowess or stoicism, but also by emotional intelligence, empathy, and vulnerability.

This broader perspective dismantles the notion of a single “right” way to be a man, creating space for authenticity and self-expression. Embracing inclusivity fosters a more supportive and equitable society, where all individuals feel empowered to live fully and authentically, regardless of how they express their masculinity.